Engineering Services

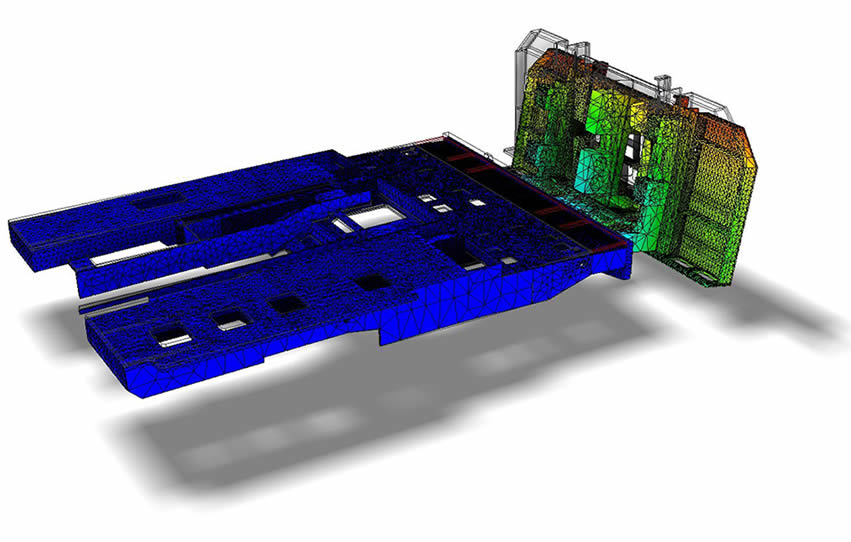

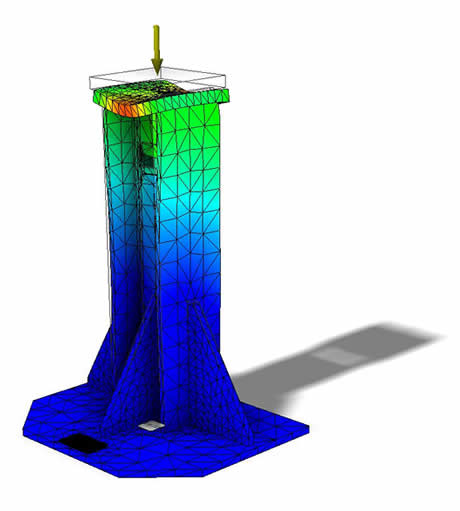

FEA (Finite Element Analysis) & Mechanical Engineering

FEA is actively used across all engineering industries: mining, sugar, energy, rail and manufacturing.

FEA is a computer-based simulation for analysing the behaviour of structures and components under a variety of conditions, and used to test varying conditions such as stress, vibration, buckling, fatigue, creep, heat, etc. on a design.

The advantage of using FEA is that it can simulate the effects of real-world scenarios on a virtual prototype prior to creating a physical prototype, thereby saving costs and reducing the number of physical prototypes required.

Because FEA offers more precise analysis than conventional hand analyses, it allows us to take into account the actual geometric shapes, loads, constraints and material properties with greater precision.

An understanding of the mechanics of materials, FEA theory, and engineering experience is vital in getting a reliable result.

We offer linear and non-linear finite element analysis (FEA), buckling and moving load simulation, machine design and analysis, hydraulics, shock, durability, fatigue, fracture mechanics and heat transfer.

When you need real-world, practical experience gained from a wide range of industries, coupled with the analytical skills and tools needed for a positive outcome, for all sized projects, call us.

FEA can help with:

- Getting to market more quickly

- Reducing prototype costs

- Reviewing / redesigning a failure

- Reducing your risk

- Improving your bottom line